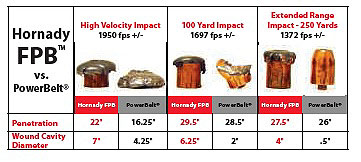

Hornady's FPB Muzzleloader Bullets  The shortcomings of Powerbelts are well known by now. The “gas check” around the base performing as anything but and the lighter weight Powerbelts (ironically the most popular) are known to have poor terminal performance due to inadequate penetration. Adequate penetration is the single most important factor in muzzleloader terminal performance (after bullet placement, of course). If a bullet fails to penetrate vital organs, it certainly cannot disrupt them by cutting and crushing. Powerbelts have been around for a long time. They were once known as “Black Belts.” They are conicals, with the appeal being easy loading. Unfortunately, all-too-often, ease of loading has been at the expense of exterior and wounding ballistics, as well as accuracy. Muzzleloading legend Doc White understood this a long time ago, opting for heavier slip-fit lead conicals (460 grain area) that offered ease of loading, yet had enough sectional density to plow through game. Though bullet lube was and is used, it presented no issue, as the velocities (with the standard White rifle 90 grain by volume of Pyrodex P) were moderate enough that bore leading was not a problem. Muzzleloaders have progressed in convenience, though convenience has a price in erratic velocities due to crushed pellets and sometimes dismal terminal performance (Powerbelts). Unfortunately, we have too often mistakenly attempted to apply small bore thinking to large bores. I cannot count the number of times I have been asked, “Why do you need a 300 grain bullet to kill a deer? That’s too heavy.” We can be ignorant of bore size and weight for caliber. We also do not seek merely to “kill a deer,” a .22 rimfire can do that. We want to bag that animal as quickly, efficiently, and humanely as possible, not just kill it. While a 300 grain bullet would be considered too heavy for a .270 Winchester, we are usually referring to .50 caliber projectiles or .45 caliber bullets with sabots. The classic .45-70 Government cartridge is a superb game-getter within its range, yet the standard US Government load (still factory loaded by Remington) used a 405 grain bullet moving at 1305 fps. It is hard to find a .45-70 Government factory loading using less than a 300 grain projectile. The 2008 Federal Premium catalog lists a 300 grain Speer Hot-Cor bullet @ 2280 fps. Hornady’s own breakthrough LEVERevolution .45-70 load features a Hornady 325 grain “Flex-Tip” bullet @ 2050 fps. Perhaps you can spot a trend here, a trend that helps illuminate the poor Powerbelt performance. Those of us with latent “center-fire" complex think velocity is good, but we want low recoil as well, an incompatible notion. One of the best, if not the best, Powerbelt sellers has been the 245 grain HP or “Aerotip.” It is also a prescription for lost game at high terminal velocities. Though no Powerbelt can be considered ballistically efficient, the lighter they get the more rapid their velocity loss becomes. A problem with “mini-conicals” is their tendency to rattle down the bore due to reduced bearing surface. Yet another problem is what must happen for a slip-fit projectile to become accurate: obturation. A pure lead projectile wants to shorten and belly-out upon firing. To do that, we need a heavy projectile that wants to remain at rest and a relatively fast, loose powder to give it a quick kick in the butt (base) to initiate obturation. Loose powder can do that, pellets often do not. Recovered Powerbelts, fired with pellets, have shown no signs of proper obturation or engraving. That accuracy can be an issue should come as no surprise under these circumstances. What Hornady has looked at here is obvious. Powerbelts do not fly well. Hornady decided to employ their proven “Flex-Tip” design to give the FPB a published ballistic coefficient of .285, which is amazingly good for a muzzleloader projectile, superior to any Powerbelt. Hornady looked at the bullet integrity necessary for high velocity impact, got away from the flyweight, too light for caliber bullets and decided on a 350 grain offering. Taking note of the penetration problems of pure lead, they experimented with different amounts of antimony and created a lead alloy less prone to pancaking on impact than pure lead. Considering the poor integrity of copper-clad and copper electroplated bullets, they developed a more substantial copper jacket to hold things together at higher velocities and when breaking bone. Rather than just guessing, Hornady already had a large body of .45-70 Government Flex-Tip data for similar applications at similar velocities. All of this is fairly straightforward, simple enough that even I can understand it. The final component is the base of the bullet. Hornady eliminated the gimmickry of a porky post and a green hula-hoop. Hornady has borrowed from the old Minie ball. It was Captain John Norton of the British 34th Infantry who made the conical’s base hollow around 1818. W. W. Greener added a wooden post to help with obturation of the Norton bullet. French officers Captain Henri-Gustave Delvigne, Colonel Louis-Etienne de Thouvenin and Captain Claude-Etienne Minié worked on bullet designs as well, finally adding an iron cup (1849) to the hollow cavity in what became known as the Minie ball. Interestingly, the “Minie Ball” was neither ball nor equipped with a post as employed in the Civil War. Nor was it the exact design of Minie or Greener. By lengthening the bullet slightly and thinning the walls of its hollow base, James H. Burton at the U.S. arsenal at Harpers Ferry, Virginia, was able to get rid of the plugs, post and metal cups used in the prior bullet designs. This was in the early 1850’s. Burton’s bullet was far easier and cheaper to make, expanded well and it was the Burton bullet that was used throughout the Civil War. Hornady has brought the Burton bullet up to date using modern manufacturing techniques, a suitable jacket and Flex-Tip nose technology. Hornady’s FPB is scheduled for general release late this spring. I’m looking forward to testing them in a number of muzzleloaders with both loose powder and pellets to see how they fly. A full review will be forthcoming on Guns & Shooting Online. |