|

Performance Characteristics of Selected Knife Steels By Gary Zinn There are many internet sources of information on knife steels. These range from charts listing the composition of various steel alloys to articles and videos that focus on the cutting performance and other attributes of particular knives, featuring specific blade steels.

One

source of information on steel performance I have found to be

instructive is titled “Knife Steel Comparison and

Charts,” posted

on the Blade HQ website (www.bladehq.com).

This document, accessed by clicking a tab labeled “Knife

Steels”

on the home page of the website, features a numeric and graphic

evaluation of 22 blade steels, in terms of key performance

characteristics. There are over 100 steels used for making knives. The 22 steels covered in the guide are mostly modern, high-tech blade steels, made by Crucible Industries, Bohler Uddeholm, Carpenter Technology, and others. There are some oldies but goodies, though, such as 1905 and D2. This guide may not cover your favorite steel, but it does include a selection of the most popular, innovative, and proven blade steels being used today. Here

are the steels included in the Blade HQ guide. The majority are

stainless steels, but there are seven carbon or tool steels, too. Most

are proprietary products (makers noted), with four generic

steels in the carbon and tool steels group.

Stainless

steels

(chromium content 13% or greater)

Bohler

Uddeholm:

M390, Elmax, N690 Carpenter:

CTS-204P, CTS-XHP

Crucible:

CPM-20CV, CPM-S90V, CPM-S110V, CPM-S30V,

CPM-S35VN, CPM-154, 154CM

Myodo:

H1 Takefu:

VG-10 Zapp:

LC200N

Carbon

and tool steels

(chromium content less than 13%)

Crucible:

CPM-M4, CPM-3V, CPM-4V Generic:

A2, O1, D2, 1095

Each

steel is evaluated in terms of four performance characteristics: edge

retention, toughness, corrosion resistance, and ease of sharpening. The

performance of each steel, against each characteristic, is scored

on a 1 - 10 ordinal scale. (1 is poor performance, 10 is exceptional

performance.) These scores give a snapshot view of the performance

of each steel, and steels can be compared with one another. It

occurred to me that overall comparisons among steels could be

facilitated by summing the four performance scores for each steel,

and then listing the steels by those total scores, which ranged from

27 points to 18 points.

27

points:

CPM-3V, CPM-4V, H1

26

points:

CTS-XHP,

CPM-S35VN, LC200N

25

points:

CPM-S30V

24

points:

M390, Elmax, CTS-204P, CPM-20CV

23

points:

A2, 1095

22

points:

O1, VG-10,

N690

21

points:

CPM-M4, D2 20 points: CPM-154

19

points:

CPM-S110V, 154CM

18

points:

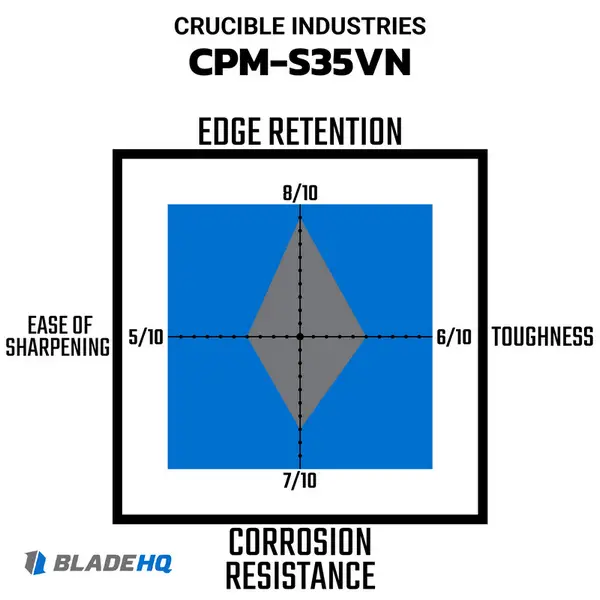

CPM-S90V Each evaluation is shown on a graph, which is quite easy to interpret. Here is an example, the performance evaluation for CPM-S35VN.

Illustration

courtesy of Blade HQ.

Note

that S35VN is a steel that is well-balanced, in the sense that it has

similar scores in all four performance characteristics, ranging from

8 of 10 in edge retention to 5 of 10 in ease of sharpening. A total

of eight steels showed similar performance balance. I have noted

these steels in bold type in all lists. Balanced versus unbalanced steels A steel that is well-balanced in performance characteristics has an intuitive appeal, but this does not mean that unbalanced steels are necessarily inferior. For instance, consider 1095 steel.

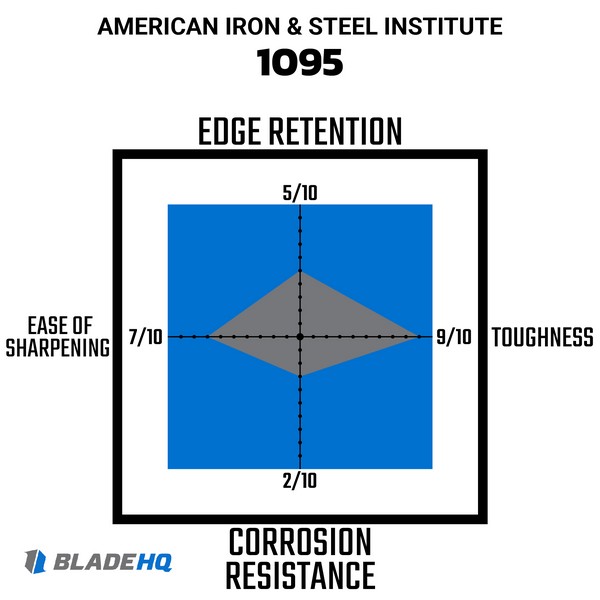

Illustration courtesy of Blade HQ. As the chart shows, 1095 is not nearly as balanced as is S35VN. The obvious imbalance is that 1095 is very tough, but has little corrosion resistance. It is also below average in edge retention, a limitation that is compensated for by ease of sharpening. 1095 is a steel that needs more caring for than S35VN, specifically steady attention to rust prevention measures and frequent sharpening. Despite its performance imbalances, 1095 is a time proven, dependable, and effective knife material, as long as the user keeps in mind its characteristics. Well-balanced steels are nice, but user preferences regarding performance may sometimes favor a steel that is not balanced. Keep this in mind when evaluating and comparing steels. Interpretation of total points One should be thoughtful in drawing conclusions from the total points list. Simply assuming that high scoring steels are good, while low scoring ones are poor, would be, well, simplistic. For instance, CPM-3V and -4V make the very top of the list. Blade HQ opines that CPM-3V and -4V are, “perfect blade steel for a fixed blade knife” because they score high in edge retention and toughness, with medium corrosion resistance and ease of sharpening. Thus these are popular steels in heavy-duty survival/bushcrafter type knives, from major name production and custom knife makers. Such knives tend to be pricey, though.

H1,

the other steel garnering 27 points, also comes with a caveat

attached. H1 scores a 10 for corrosion resistance; Blade HQ

comments that “you can literally leave it in salt water

forever and

it won’t rust.” H1 also scores quite well in

toughness and ease

of sharpening, but is rated with very poor edge retention (2 of 10). H1

is most commonly found in knives designed to be used in marine

environments. Sticking out like sore thumbs at the bottom of the total score list are CPM-S90V and CPM-S110V. Crucible Industries seems to have set out to see how far they could push the ability of a knife steel to hold an edge when developing these alloys. If so, they succeeded, for S90V and S110V score 9 and 10, respectively, on the edge retention scale. Unfortunately, these steels are one trick ponies, for they pretty much suck in toughness and ease of sharpening (they are almost impossible to hand sharpen), and are no better that okay in corrosion resistance. They only make sense if the user values edge retention far above any other consideration. Between these outliers are a lot of good steels. CPM-S35VN is the most popular steel currently used on production and semi-custom knives. M390 and Elmax are steadily building a reputation as outstanding products. VG-10, N690, CPM-154 and 154CM are finding their way into a lot of moderate priced knives, and even some budget items. Proven carbon and tool steels, including 1095, A2, O1, and D2 are in the mix, joined by the newer CPM-M4. Further parsing of the data

The

total points list gives one perspective on these 22 steels, while

breaking down the four blade performance characteristics gives

another. To do this, I built lists that focus on each of the four

performance characteristics. Each list begins by noting the average

score among the 22 steels in question and noting the best and worst

scoring steels. Then I defined high, moderate, and low score ranges

for each characteristic and listed each steel according to where its

score fell among these ranges. Ordinal scores of each steel are

noted in parentheses, for each performance characteristic. Edge retention (average = 7.1 of 10) Best — CPM-S110V (10); Worst — H1 (2)

Toughness (average = 6.0 of 10) Best — CPM-3V (10); Worst — CPM-S110V(2)

Corrosion resistance (average = 5.7 of 10) Best — H1 (10); Worst — CPM-M4 and 1095 (2)

Ease of Sharpening (average = 4.3 of 10) Best — H1 (8); Worst — CPM-S90V and CMP-S110V (1)

(Concerning

the ease of sharpening scale, be clear that a high number means that

the steel sharpens easily, while a low number denotes a difficult to

sharpen steel.) The individual performance characteristics tables have a lot of usefulness. For instance, suppose that I want a knife that has high edge retention, along with no worse than moderate performance in terms of the other characteristics. I can quickly see that Elmax, CTS-XHP, CPM-S30V, CPM-S35VN, and CPM-4V are the steels that fit the criteria, while the other steels with high edge retention filter out, because they have low performance in toughness, corrosion resistance, or ease of sharpening. With this information in hand, I can shop among knives with these steels, to choose one which best satisfies any other preferences I have. The point is that noting the performance characteristics, individually or in combination, helps focus attention on the knives that will best meet the needs and preferences of the user.

Conclusion Users of this information should understand that the performance scores assigned to the steels are, ultimately, judgment calls. Thus individual scores are subject to discussion and even mild disagreement, in some cases. However, I have experience with using and sharpening knives with several of the steels in question, and the only relative scores shown above with which I would strongly disagree are the ease of sharpening scores for A2 and D2 steel. I would score these steels a point higher in ease of sharpening; understand, though, that I sharpen them on diamond plates, as they are difficult to sharpen on conventional bench stones. I do not have experience-based opinions on the toughness scores, because I do not torture test my knives. Also, I am not inclined to question most of the corrosion resistance scores shown, for my knives all get common sense rust prevention care, whatever the steel may be. That said, I recently got my first knife with A2 steel, and my early experience is that it is not as rust resistant as the score shown above implies. (A2 is given a score of 5 on corrosion resistance, D2 a 4, and 1095 a 2.) I have a lot of experience with D2 and 1095, and I cannot buy that A2 is more rust resistant than D2, but A2 is somewhat better than 1095. I would give A2 a score of 3 in corrosion resistance. The bottom line is that the scores shown above are indicative, rather than definitive, but I feel that they are valid enough overall to give useful guidance when one wishes to compare the performance characteristics of various steels. This is why I felt that it was worthwhile to write and post this article. The Blade HQ article, along with a similar article on the Knife Informer website (referenced below), provides a brief narrative on both the outstanding features and notable limitations of each steel. This information supplements and interprets the performance scores, so is worth paying attention to when one is looking closely at a steel.

Finally,

the Blade HQ article notes that edge retention, toughness, corrosion

resistance, and ease of sharpening are important determinants of

performance, but are not the whole story. The heat treatment of the

blade, blade geometry (especially spine thickness and type of primary

grind), sharpening parameters (type and angle of secondary edge

grind), and the cutting tasks for which the knife will be used are

interacting factors that also influence knife performance. Anyone

shopping for that just-right new knife, for a particular use or

purpose, has a lot to think about. Hopefully, the information

conveyed in this article will be helpful to the thought process,

rather than confounding. Addendum: Additional steels from Knife Informer Guide to the Best Knife Steel

The

Knife Informer website has an article titled “Guide to the

Best

Knife Steel” that contains information similar to that in the

Blade

HQ guide, including mostly consistent performance ratings on many of

the same steels. The Knife Informer guide includes eleven common

steels in addition to those in the Blade HQ guide. Here is a set of

lists, organized as above, on these additional steels. Total points 28 points: 440A (Generic), 420HC (Latrobe) 23 points: N680 (Bohler Uddeholm) , 14C28N (Sandvik) 22 points: AUS-8 (Aichi), CTS-BD1 (Carpenter) 21 points: ATS-34 (Hitachi), 440C (Generic) 20 points: 8Cr13MoV (Ahonest), 13C26 (Sandvik)

16

points:

ZPD-189 (Hitachi) As before, labels printed in bold designate well-balanced steels. In breakdown lists below, ordinal scores of each steel are noted in parentheses, for each performance characteristic. Edge retention (average = 4.2 of 10)

Toughness (average = 6.0 of 10)

Corrosion resistance (average = 5.5 of 10)

Ease of Sharpening (average = 6.4 of 10)

I do not feel a need to add commentary on this group of steels, for the Knife Informer article includes brief comments on each one. Beyond that, anyone interested in one or more of them can evaluate individual or combined performance characteristics as appropriate, and can also compare them with steels in the larger main group. |